Bar Cutting Machine | GQ 40H

- Apr 24, 2025

- 5 min read

Updated: Apr 25, 2025

In the fast-paced world of construction and metal fabrication, the tools you choose can make all the difference. The right equipment not only ensures precision but also significantly boosts productivity. This is where the bar cutting machine (GQ 40H) shines. With its powerful features and reliable performance, it's a go-to choice for professionals across the industry. This post explores the specifications, features, and advantages of the bar cutting machine (GQ 40H), showcasing why it's an excellent investment for your projects.

Understanding Bar Cutting Machines

Bar cutting machines are specialized tools designed for cutting various metal bars, particularly steel rods and rebar. These machines are essential in construction, where rebar is crucial for reinforcing concrete. The bar cutting machine (GQ 40H) is specifically built to handle demanding cutting tasks with high efficiency.

For example, consider a construction project that requires cutting rebar for a foundation. Using the bar cutting machine (GQ 40H) can drastically speed up the process compared to manual cutting methods. With its ability to cut bars efficiently, it helps expedite timelines and contributes to project success.

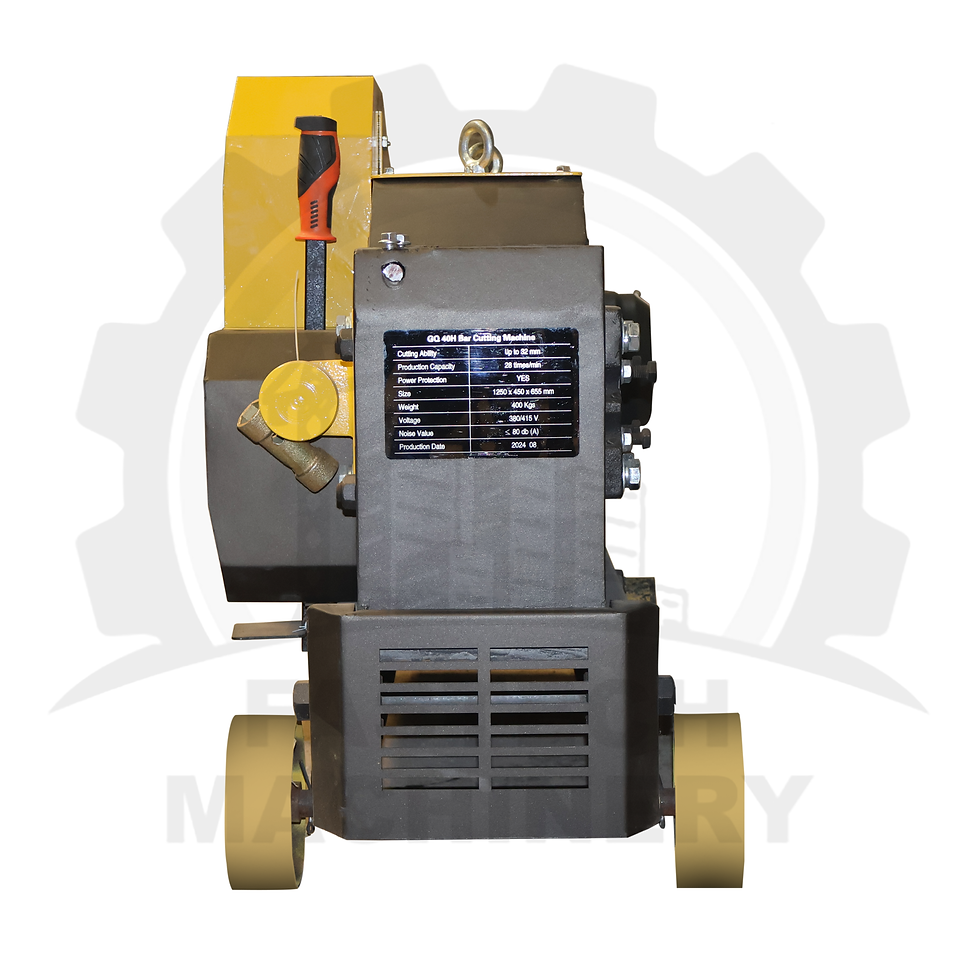

Technical Specifications of Bar Cutting Machine (GQ 40H)

To appreciate the bar cutting machine (GQ 40H) fully, let's break down its technical specifications:

Cutting Ability

The bar cutting machine (GQ 40H) can cut metal bars up to 32mm in diameter. This capability makes it versatile enough for both small-scale residential projects and large commercial developments.

Production Capacity

With a production capacity of 28 cuts per minute, the bar cutting machine (GQ 40H) allows for swift processing of materials. For instance, in a typical work shift of 8 hours, this machine can produce up to 13,440 cuts, making it invaluable for meeting tight project deadlines.

Power Protection

This bar cutting machine (GQ 40H) includes advanced power protection features, ensuring that it runs smoothly without interruptions from electrical fluctuations. This reliability enhances the machine's lifespan and performance.

Dimensions and Weight

Measuring 1250mm x 450mm x 655mm and weighing 400kg, the bar cutting machine (GQ 40H) provides stability during operation. Its weight minimizes vibrations, which is crucial for achieving precise cuts.

Voltage

Designed to operate at 380/415V, the bar cutting machine (GQ 40H) is compatible with standard electrical systems found in many regions, ensuring ease of use in various locations.

Features of Bar Cutting Machine (GQ 40H)

The bar cutting machine (GQ 40H) isn’t just about numbers; it’s packed with features that improve usability and safety.

Durability

The bar cutting machine (GQ 40H) is constructed with high-quality materials, making it robust enough to face the tough conditions of construction sites. This durability reduces maintenance needs and prolongs the machine’s life.

User-Friendly Operation

The intuitive design of the bar cutting machine (GQ 40H) simplifies operation. Users can quickly learn how to use it, cutting down on training time. For example, a new operator may require only a few hours of guidance before using it independently.

Enhanced Safety Measures

Safety remains a top priority in any work setting, especially in construction. The bar cutting machine (GQ 40H) includes safety features that protect operators from potential hazards related to cutting operations.

Maintenance Requirements

Regular maintenance is vital for any equipment’s performance. The bar cutting machine (GQ 40H) is designed for straightforward upkeep, with components that are easy to access for cleaning and servicing.

Benefits of the Bar Cutting Machine (GQ 40H)

Purchasing a bar cutting machine (GQ 40H) presents significant advantages for construction businesses.

Increased Productivity

Thanks to its high cutting capacity and fast production rate, the bar cutting machine (GQ 40H) can dramatically enhance productivity. Completing more jobs in less time can lead to improved project delivery times, which satisfies clients.

Cost-Effective Solution

While the initial investment in the bar cutting machine (GQ 40H) may appear substantial, its efficiency translates into long-term savings. For instance, reduced labor costs and less machine downtime contribute to its cost-effectiveness, making it a smart financial choice.

Superior Quality Cuts

The precision of the bar cutting machine (GQ 40H) guarantees clean, accurate cuts. In high-stakes construction projects, where the integrity of materials directly affects safety and stability, having a machine that delivers quality is essential.

Versatility

The ability to handle a variety of bar sizes makes the bar cutting machine (GQ 40H) a versatile asset for different projects. Whether you're working on a small residential build or a large infrastructure project, this machine adapts to your needs.

Applications of Bar Cutting Machine (GQ 40H)

The bar cutting machine (GQ 40H) is utilized in several sectors:

Construction Industry

In construction, the bar cutting machine (GQ 40H) is frequently employed to cut rebar for concrete reinforcement. Its efficiency helps contractors adhere to tight schedules, allowing them to take on more projects simultaneously.

Metal Fabrication

Metal fabricators value the bar cutting machine (GQ 40H) for its precise cutting capabilities. Custom projects often require specific dimensions, and this machine delivers that accuracy consistently.

Infrastructure Projects

Infrastructure projects, such as building bridges and highways, demand large amounts of rebar. The bar cutting machine (GQ 40H) provides a reliable cutting solution, ensuring that projects stay on track.

Essential Maintenance Tips for Bar Cutting Machine (GQ 40H)

To ensure the bar cutting machine (GQ 40H) operates optimally for years, follow these maintenance tips:

Regular Inspection

Perform routine checks on critical components, including the cutting blades and motor. Identifying wear and tear early can prevent larger issues and costly repairs later on.

Cleaning

Keeping the machine free of debris and residue enhances performance. Regularly cleaning the cutting area and any parts in contact with material is beneficial for maintaining efficiency.

Follow Manufacturer Recommendations

Always consult the manufacturer’s guidelines for specific maintenance schedules and recommendations. Following these instructions will help keep the machine running smoothly.

Professional Servicing

For issues requiring specialized attention, seek help from professionals familiar with the bar cutting machine (GQ 40H). This ensures that the machine remains in peak condition without risk of damage.

Final Thoughts

The bar cutting machine (GQ 40H) is a powerful tool designed to meet the demands of various industries needing metal cutting solutions. With a cutting ability of up to 32mm and a production capacity of 28 cuts per minute, the bar cutting machine (GQ 40H) stands out as an optimal choice for professionals seeking reliability and efficiency.

Investing in the bar cutting machine (GQ 40H) not only enhances productivity and cost-effectiveness but also guarantees superior quality cuts that are crucial for construction tasks. By incorporating the bar cutting machine (GQ 40H) into your operations, you are equipping your team with a machine that elevates their capabilities and ensures successful project completion.

When choosing a bar cutting machine, the bar cutting machine (GQ 40H) offers a compelling combination of innovative design and robust performance tailored to meet the needs of modern construction.

Comments